Microwave Belt Dryers Conveyor for agricultural use

Points of strength:

- Reduced process times

- Modular systems adaptable to any type of product

- High energy efficiency

- Suitable for the treatment of thermolabile materials

- Recognition of white certificates for reduced energy consumption

- Process temperature containment

Project description

Purple medic drying conveyors

Project details

Industry:Other Industries (agriculture)

Project description

Molluscicides pellet drying system

Project details

Industry:Other Industries (agriculture)

Project description

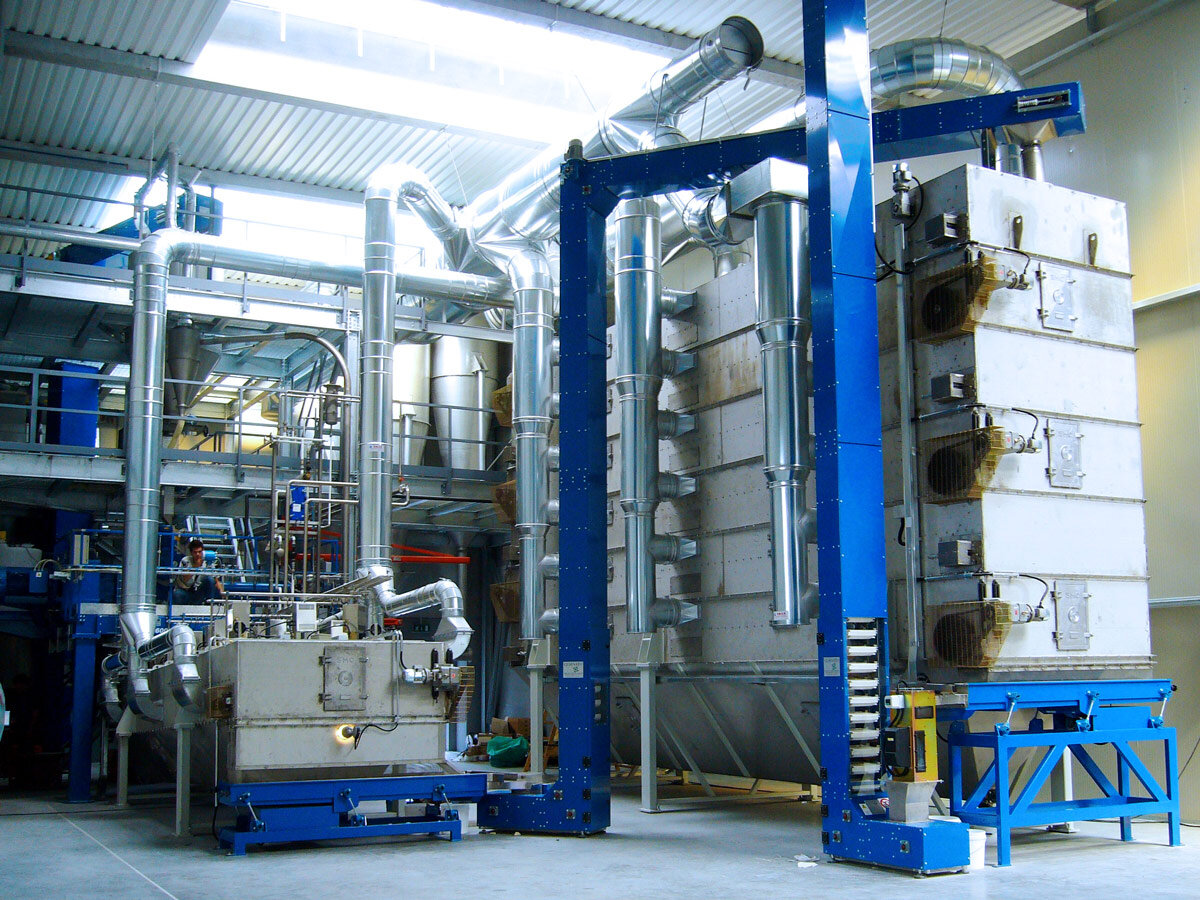

30000 kg/h Fertilizer pellet drying plant

Project details

Industry:Other Industries (agriculture)

How Microwaves works:

Microwaves are a form of electromagnetic energy with frequencies between 300 MHz and 300 GHz, generated by the magnetron under the joint force of magnetic and electric fields perpendicular to each other.

Microwaves penetrate materials and release their energy in the form of heat as polar molecules (those with positive and negative ends – such as water) vibrate at a high frequency to align with the frequency of the microwave field (2.45 GHz).

This vibration generates heat. Many studies have now been published showing no difference in the stability and physicochemical properties of materials dried with microwave processing, when compared to other drying methods.

Since microwaves are non-ionizing and do not have an amount of energy necessary for the formation of free radicals, there are no conditions created during microwave drying that generate product instability.

This characteristic can greatly accelerate the drying of the material, which is why our dryers are so efficient and advantageous in terms of low energy consumption.

English

English Italian

Italian